Works

Effect of Layer Thickness and Orientation of 3D Printed Parts on the Mechanical Properties

Portfolio

SLA Printing Research

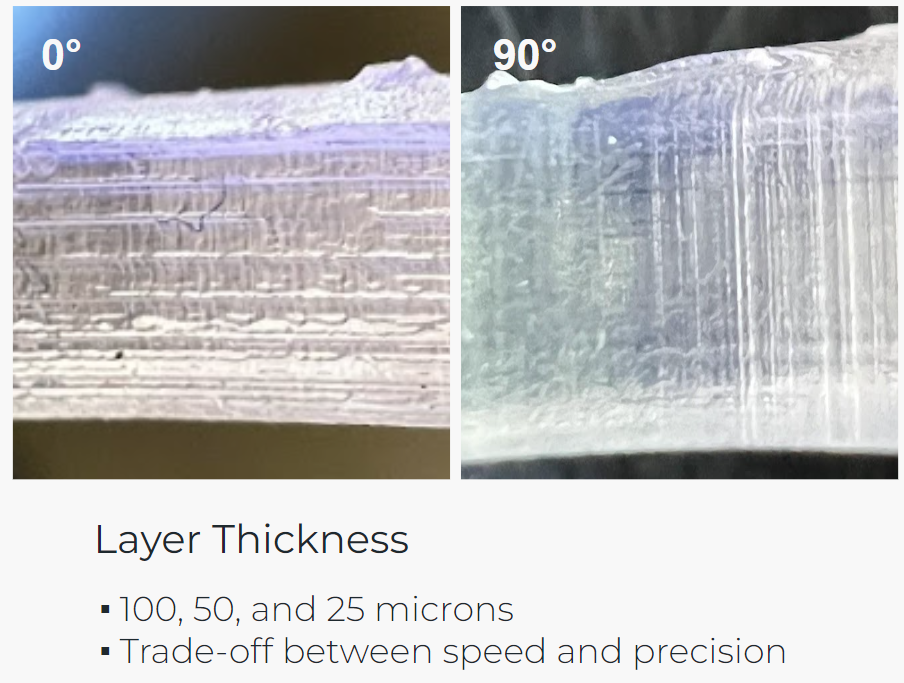

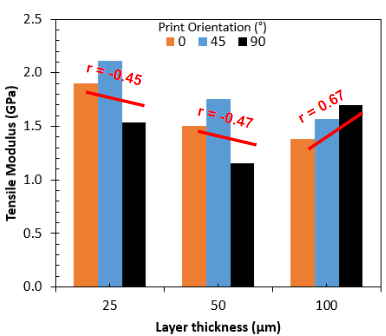

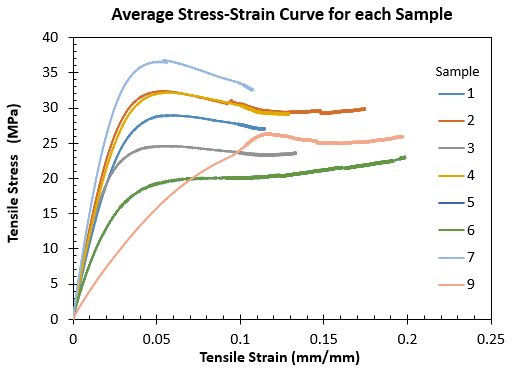

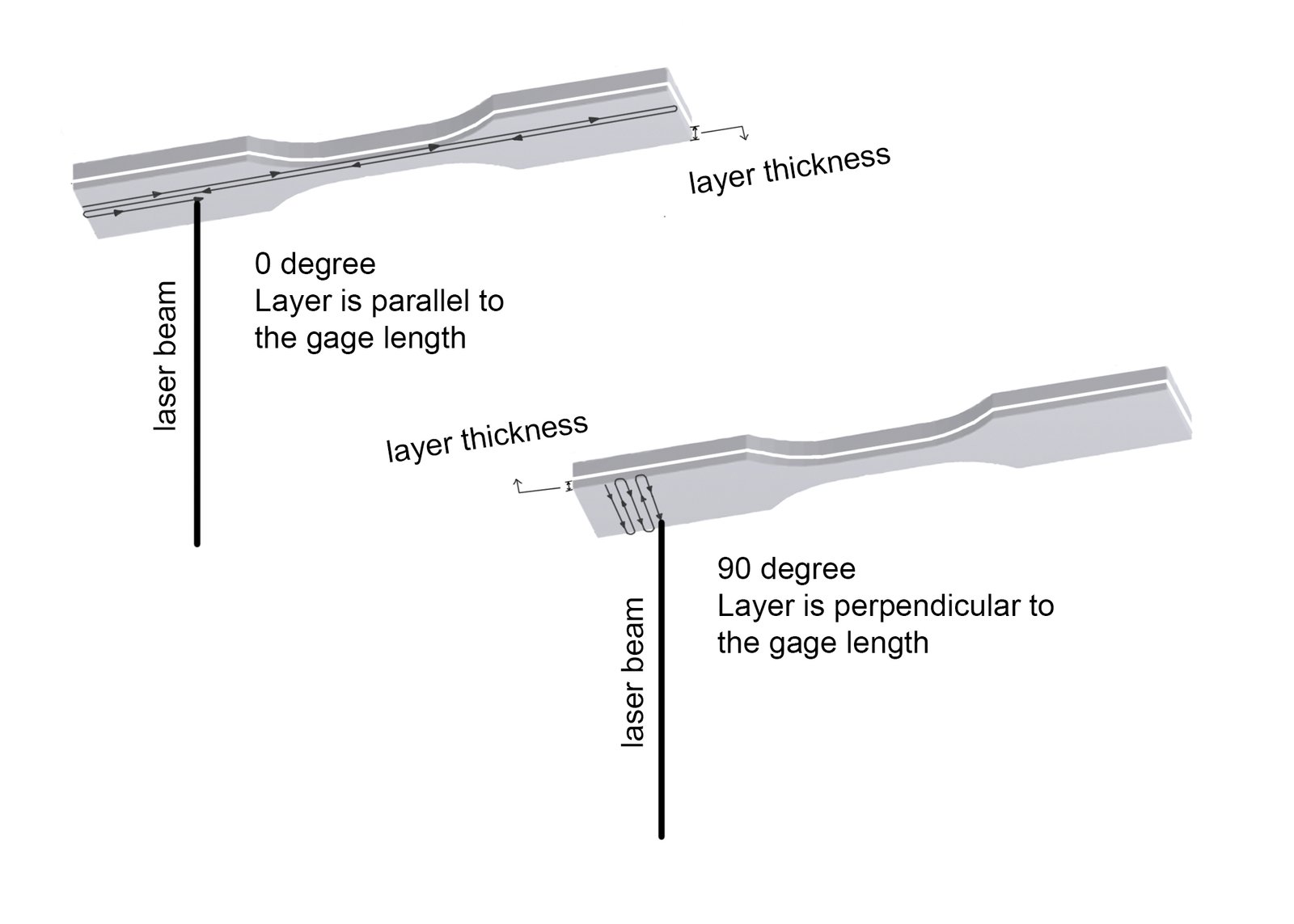

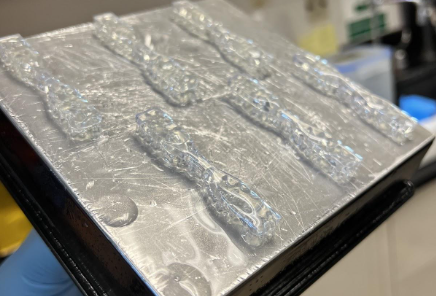

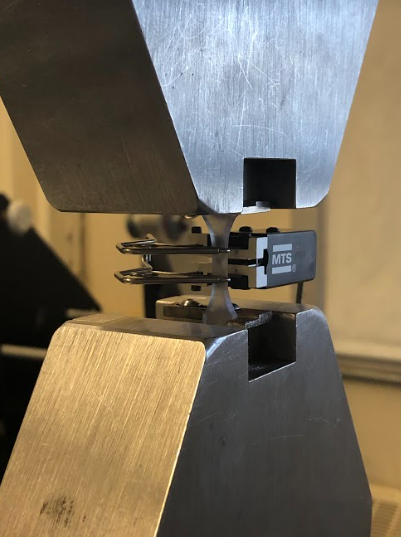

With the many advancements in 3D printing technology in the last few decades, there is an increased need for a greater understanding of fundamental print variables. Additive manufacturing (AM) is becoming more viable for large commercial processes and more accessible to 3D printing hobbyists. The field of additive manufacturing would benefit from stronger prints to allow for a wider range of applications and innovations. Stereolithography additive manufacturing (SLA) is used to investigate the effect of layer thickness and print orientation of 3D printed parts on the mechanical properties. Using clear resin, parts were 3D printed with three layer thicknesses (25µm 50µm and 100µm) and three print orientations (0°, 45°, 90°). Tensile tests were performed in accordance with ASTM D638 and results showed a positive correlation between the Young’s modulus and print orientation for parts with 100 micron layers, with the 90° specimens being the stiffest of the three print orientations in the 100 micron layer thickness group. Among all samples, the 25µm 0° print proved to be the stiffest parts– a sacrifice for its brittle nature with low strain. Even so, the almost linear trends present in the 100µm samples were absent from the thinner layer prints, raising the belief that at a certain thickness, the print orientation provides no significant trends. These results raise the understanding of SLA printing parameters and the effect on printed parts, enabling more efficiency and raising the ceiling on the upper limits of 3D printing.

This research project is affiliated with the NJ Governor’s School of Engineering and Technology and conducted as a group project. In October 2022, it was presented at the MIT Undergraduate Research Technology Conference and published in the IEEE Xplore database. DOI: 10.1109/URTC56832.2022.10002172

In the group project, I led the data organization and analysis, compiling over a dozen different trendlines and statistical analyses to find the best optimizations. I also led the LaTeX formatting and paper adaptation for the MIT URTC and was one of two members who presented findings at MIT.